HVACON FORCE System

By adding extra negative electrons into a power system with HVACON FORCE, energy loss, power consumption and system harmonics are greatly reduced improving the overall performance and flexibility of your vessel.

FORCE system uses the naturally occurring Tour- maline (mineral based) composition to boost electrical performance in shipboard systems and power transmissions. The Tourmaline has been known since the 1800’s to be piezo and pyro electric in nature

FORCE system has been operating globally since 2008. It is tested, and type-approved for marine installations with patents world-wide.

Typical ROI is accomplished within two years. The systems installed in 2008 remain functional at 100% and are maintenance free.

More advantages

• HVACON FORCE will deliver predicted savings regardless of how many other power saving systems are installed. HVACON FORCE does not conflict or negate any saving potential from other energy saving initiatives.

• HVACON FORCE system will prolong the lifetime of connected electrical consumers and electronic devices while reducing failure rates.

• Tourmaline is a naturally occurring mineral without side effects or challenging environmental handling requirements.

HVACON can save your cruise ship a total of 20-25% on power and fuel, if you combine our FORCE and HVAC Energy Saving Systems.

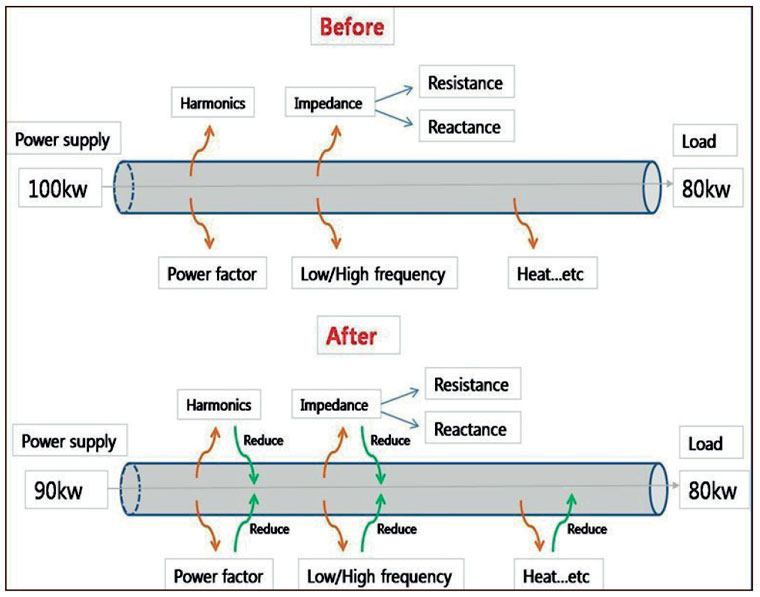

Reduce your power consumption

Energy savings experienced by installing FORCE system has been recorded as high as 15%. Savings fluctuate depending on network architecture and networks components.

The system is applicable to all electrical installations on all types of ships, with the largest savings occurring on vessels with high power consumption and limited spare capacity.

Vessels with a large ventilation requirements can reduce fuel consumption as much as 20-25% when combining FORCE system and HVACON HVAC Energy Management Systems.

The benefits of the system can be seen in lower overall fuel consumption with ancillary benefits to CSR metrics through lower CO2 emissions.

The power enhancement system increases

• conductivity/ability to conduct electricity.

• electric charge rate.

• effect on electron power transfer.

• Increase lifetime of connected electrical consumers and electronic devices.

• Short ROI.

The power enhancement system reduces

• harmonic distortion.

• impedance.

• high/low frequencies.

• electrical reactance.

• electron consumption.

• equipment malfunction.

• fuel consumption.

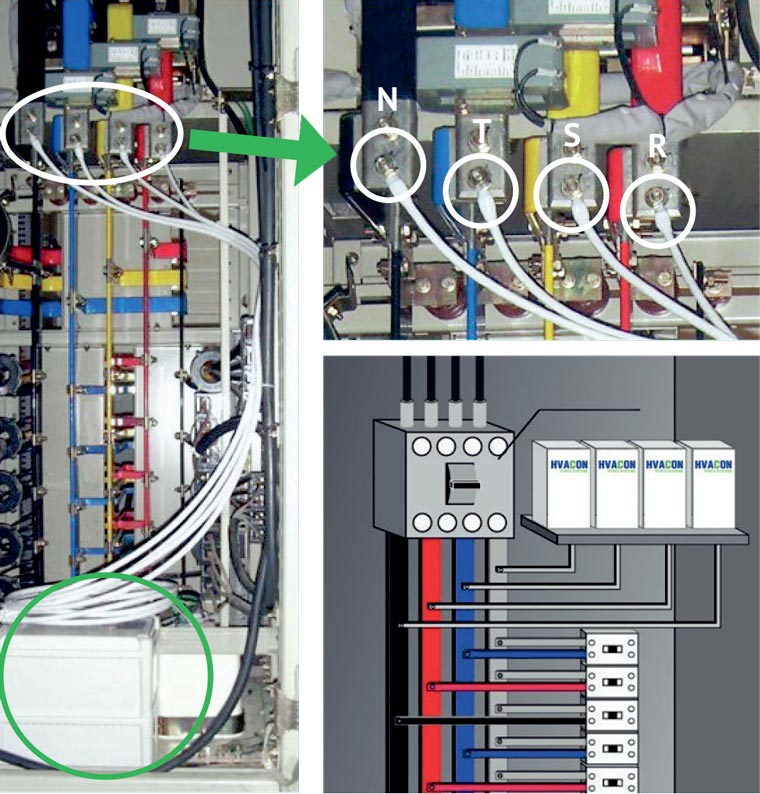

Hvacon manages the installation

HVACON is an experienced installation partner on cruise ships.

HVACON will conduct onboard surveys, feasibility studies and analyze the results. Projects are offered and managed “turn-key”, with commissioning and handover accomplished side-by-side with the owner or operator.

FORCE system equipment is installed in parallel with the existing installations. Connections are made to existing switchboard busbars or on outgoing termination points, without changing existing installation/terminations. It is simple and easy to install, and the size and weight of a FORCE component is only 0,03 m3 and 485 lb/220 kg for a 1.0 MW system (scalable).

You will not need extra manpower in daily operations as the system needs no maintenance. It is simply a mineral in a box, so it does not malfunction – instead it comes with an 8-year guarantee.

We will subsequently assist you with service, power measurement and graphs in order to document your power savings.

Class approval will be handled by FORCE Systems.

Could it be any easier?

THD and heat dissipation is reduced with up to 30%.

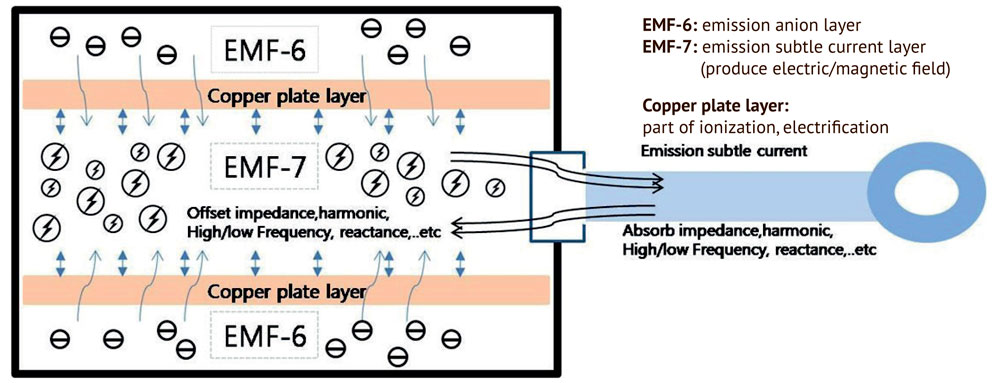

The technology

The main component of the FORCE system is the EMF-7, which works in a completely different way than other known power-saving systems. The EMF-7 features hybrid minerals that produce electromagnetic waves. These waves help the electric flow pass unobstructed from the source to the target, thus reducing power consumption.

In order to reduce the resistance and improve the current flow in the installation and consumers, FORCE system produces surplus negative electrons.

This increases the density of free electrons while harmful factors such as impedance, harmonic distortion and high/low frequency are absorbed or counteracted.

Measurements and Test results

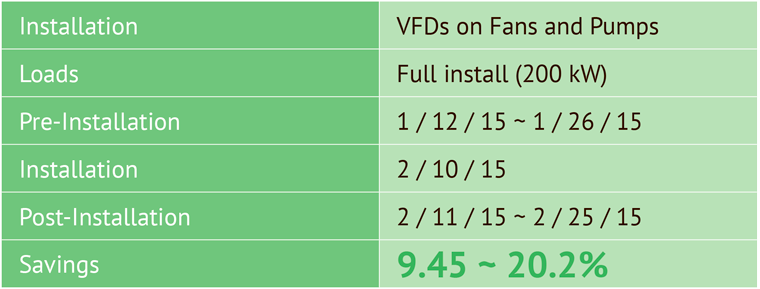

Below example is from an installation with fans and pumps, operated with VFDs, to measure not only the saving but also the THD reduction.

Ship application frequently contain VFD motors to operate their various pumps, fans and other electrical motors, while VFD individually use less energy than their traditional counterparts they create the unintended negative consequence of generating harmful and wasteful current harmonic distortion. Harmonic distortion wreaks havoc on the quality of energy that is delivered to the entire facility causing waste and increased energy consumption.

During the course of this project Maximum HD, Daily wattage and Daily wattage at same flow were

compared, both before and after FORCE was installed.

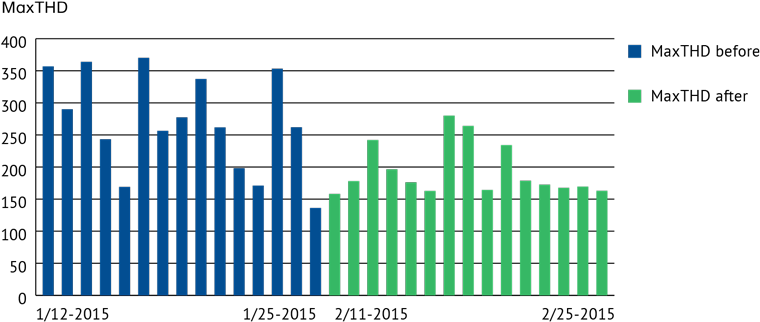

Max THD, before and after FORCE Installation

1. The above chart depicts Maximum harmonic distortion (HD) both before and after FORCE was installed, an apparent reduction can be observed.

2. While no HD mitigation product can completely eliminate HD, any reduction will lead to better power quality, less wear and tear on equipment and reduced energy consumption.

3. After FORCE was installed a noticeable reduction in HD can be observed. The Overall Maximum HD reduction rate was nearly 30%.

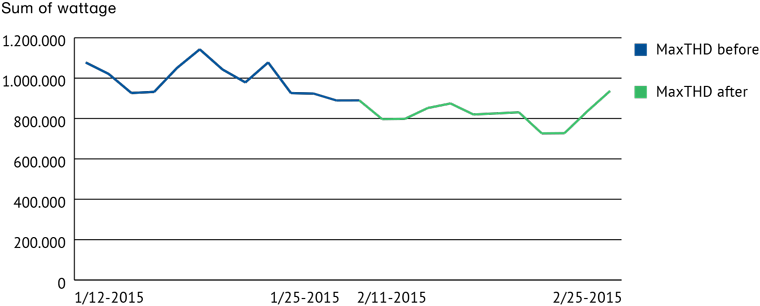

Average wattage, all days (excluding digester), 20.2% savings

1. The above chart depicts average wattage from each day during the pre-FORCE and post-FORCE periods.

2. A reduction in average wattage is generally an indicator of a reduction in both kW and kWh consumption (if all things such as lighting, length of usage and amount of flow remain the same).

3. During the post period digester equipment was added, therefore separate metering only on that digester equipment was performed and that wattage was deducted from the Post FORCE period

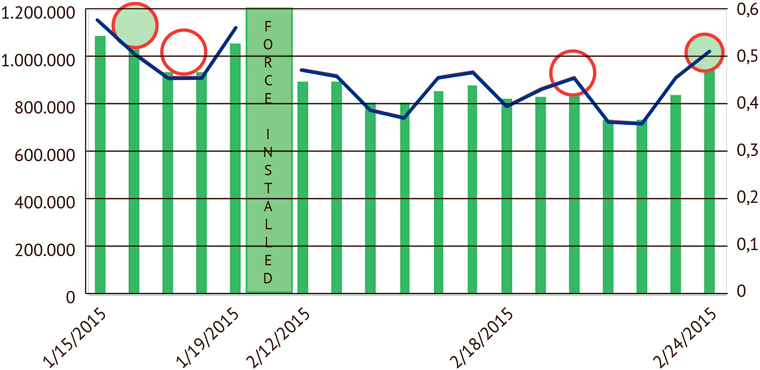

Wattage by same flow, 9.45%

1. The above chart depicts the sum of wattage (green bars) from each day during the pre-FORCE and post-FORCE periods. For comparison purposes wattage from days with the same flow (red line) were also analyzed.

2. A reduction in daily wattage is important because it not only leads to a lower monthly utility bill through lower Kwh but also through lower kW, many utilities charge extra for peak levels of kW.

3. An apparent reduction in overall wattage can be observed in addition to a reduction in wattage on same flow days.

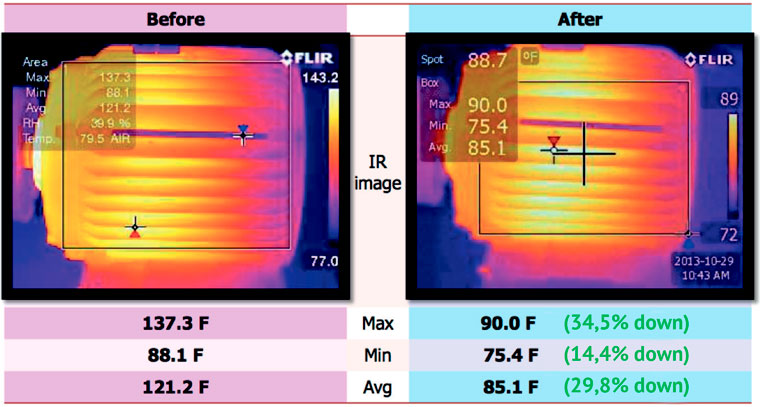

Running Temperature drops on Motor

1. Temperature drops observed on pump motor.

2. Average temperature dropped from 121.2 F (Pre) to 85.1 F (Post) by 29.8%.

Certificate

• CE and UL safety certificate

• KRS Class approval

• Award the patent of 70 countries over the world and ISO certified

• Function test by SGS and TÜV