HVACON FORCE

In combination with our HVAC energy optimizing solutions, we can also provide your fleet with an FORCE installation.

The system is applicable to all electrical installations on all types of ships, with the largest savings occurring on vessels with high power consumption and limited spare capacity.

Vessels with a large ventilation requirements can reduce fuel consumption as much as 20-25% when combining FORCE system and HVACON HVAC Energy Management Systems. The benefits of the system can be seen in lower overall fuel consumption with ancillary benefits to CSR metrics through lower CO2 emissions.

ENERGY OPTIMIZATION

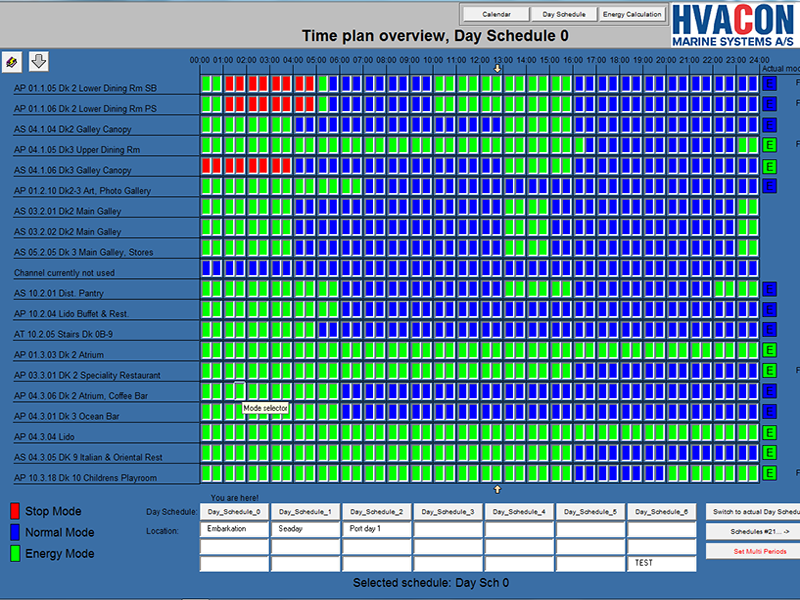

HVACON Marine Systems A/S have developed the TimeSchedule© and Energy Saving System© Program, which is used for HVAC Energy optimization and savings on cruise vessels.

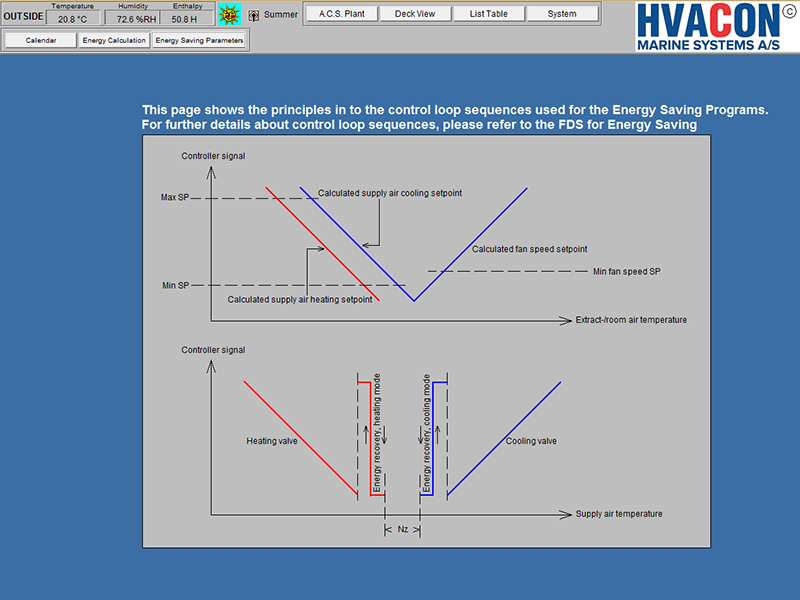

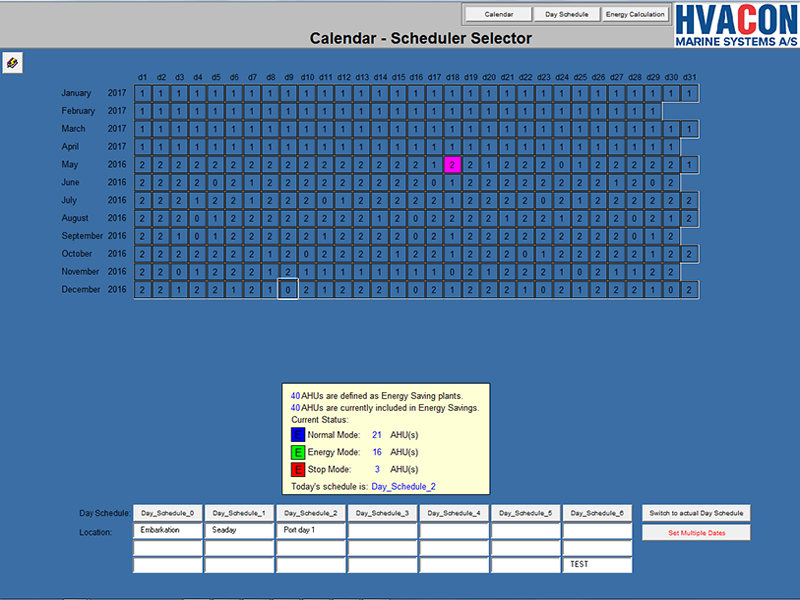

The owner’s new building requirements often specify excessive capacity for HVAC systems, in order to ensure passenger comfort while cruising in tropical climates. This means that there is significant potential for operational optimisation when the vessels are in less demanding climates or in transitional periods where there are fewer passengers onboard. Furthermore, the upgrade will ensure that the system is taking advantage of the simultaneous factor for persons and for various heat sources, such as entertainment equipment, so that the cooling capacity is transferred to the areas where it is needed. The basis of this technology is to monitor the passenger flow and occupancy of each area. Ventilation is reduced to a minimum for unoccupied areas in order to save both electrical power and chilled water. Each area is controlled from a ‘TimeSchedule’, but to maintain a comfortable climate in the areas, CO2 sensors detect the passenger flow, and avoid any discomfort if the passenger flow changes.

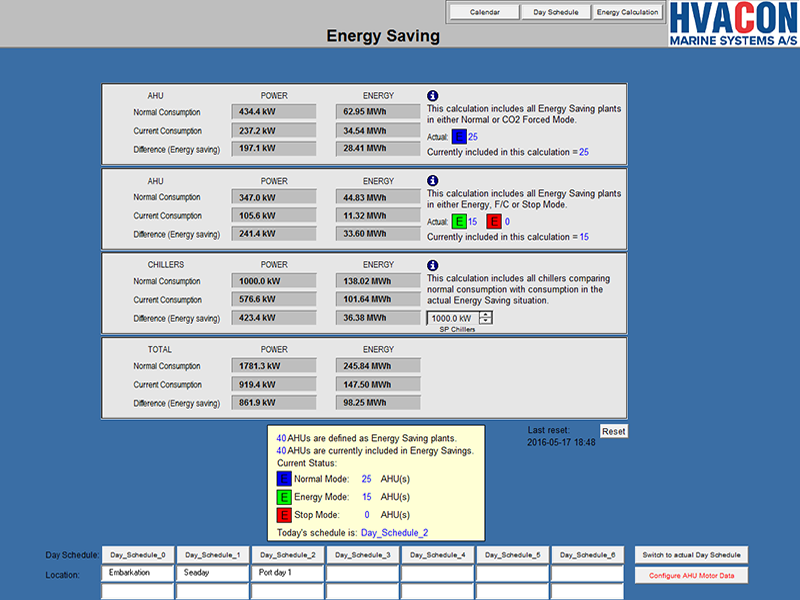

Up to 25% efficiency gains may be expected in the HVAC system by upgrading equipment onboard, changing system operational parameters, and installing customised software to better manage operation of HVAC machinery. As a consequence, the payback period is expected to be less than six months.

An ‘Energy Saving Calculation’ program can give daily reports to the operators and technical staff ashore regarding results of the HVAC energy optimization.

The new generation of the ‘TimeSchedule’ and ‘Energy Saving Calculation’ system can be interfaced to most existing HVAC HMI control systems, and is therefore applicable to most vessels, without exchanging the HVAC HMI.

Further improvement of the energy efficiency for the HVAC system is in progress and can now be implemented, which will include chilled water demand flow control, ‘Freecooling’ of chilled water for ships sailing with low outside temperatures, Unoccupied Cabin control, improvement of Return Air and Enthalpy Wheels, as well as demand air flow in Galleys.

Benefits:

- TimeSchedule© including up to 14 different schedules

- CO2 monitoring

- Parameters settings

- Return Air Control

- Energy Saving Calculation

- Yearly Calendar

- Remote Access

- Energy Reporting

- Interface to all existing HVAC control systems

- Demand control of Galley Hoods